SMT temperature profile

Home>SMT temperature profile

SMT temperature profile

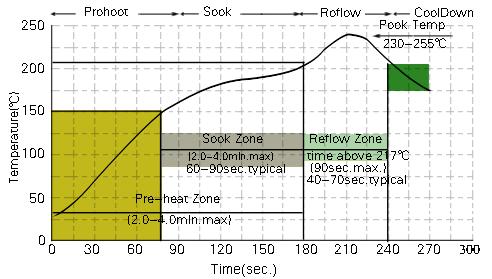

2-5-4 Temperature Profile Parameters:

Applied to Sn63∕Sn62-Ag2 solder pastes

1) Preheat Zone: The highest temperature is 2.5℃/s. Excessive rising rate will cause solder-balling.

2) Soaking Zone: Keep the temperature within the range of 149-180℃/s and the temperature rising rate less than 2.5℃/s during the soaking zone, which lasts regularly from 60s to 90s.

3) Reflow Zone: The peak temperature in the reflowing zone changes in the range of 215-235℃ Make sure the temperature stays above 180℃ for 45-60S

4) Cool-Down Zone: The temperature dropping rate during cool-down zone should be kept under 4℃/s。

Note: The curve varies according to shape of the plate and function of the devices. The circumstance parameter is suggested to be 25±2℃ by temp. and 45%-65% by humidity.

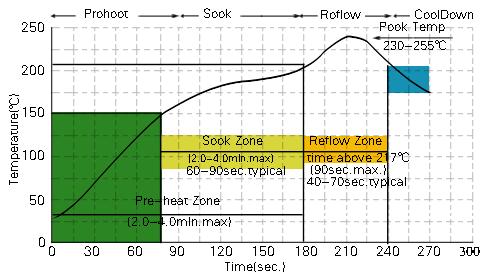

2-5-5 Recommend Reflow Soldering Temperature Profile

Applied to WH-326 WH-373 solder pastes

1) Preheat Zone: The highest temp.is 2.5℃/s in pre-heating area. Over rising rate will cause solder-balling.

2) Soak Zone:Keep the temp. within the range of 150-210℃ and the temp. rising rate under 2.5℃/s during the soaking zone. which lasts regularly from 60s to 90s

3) Reflow Zone: The peak temp. in the reflowing zone changes in the range of 230-255℃. Temperature stays above 217℃ for 40-70S

4) Cool-Down Zone: The temperature dropping rate during cool-down zone should be kept under 4℃/s。

Note: The curve varies according to shape of the plate and function of the devices. The circumstance parameter is suggested to be 25±2℃ by temp. and 45%-65% by humidity.

2-3-5 WH-138G-M Sn42Bi58 Reflow Profile

Parameters for temperature profile

1) The highest heataing rate is 2.5℃/s in pre-heating zone. Rising over fast will cause tin-balling.

2) Keep the temperature in the range of 150-210℃/s and the temp. rise no bigger than 2.5 degree/s during the soaking zone, which lasts regularly from 60 s to 90 s.

3) The peak temperature in the reflowing zone changes in the range of 230-255℃.It will stay for from 40 s to70 s over 217℃

4) The cooling rate during cool-down zone should be kept no bigger than 4℃/s。

Additional: The curve should be made according to shape of the plate and function of the devices. The circumstance parameter is suggested to be 25±2℃ by temperature and 45-65% by humidity.

Technical supports

Contact us

Address:Xingfa Road,Balitai Industrial Zone,Jinnan District,Tianjin,PR China

Tel:86-022-83981122

Fax:86-022-83981133

Email:zhongyasolder@zhongyasolder.cn

English

English 中文简体 | 中文繁体

中文简体 | 中文繁体